High-Temperature Coating for Gas Burner Head

Direct Flame-Resistant, No Peeling, No Discoloration

Customer Background

A gas appliance manufacturer reported that burner heads, exposed directly to open flames, caused conventional coatings to discolor, peel, or burn off. This not only impacted product aesthetics but also damaged brand credibility. The client sought a coating that could withstand direct flame, resist oxidation, and remain firmly attached.

Product Details

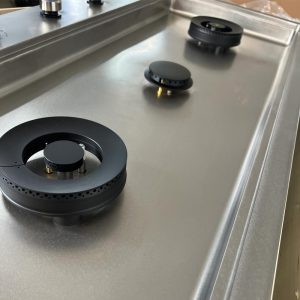

Product Name:Silicone-Based High Temperature Resistant Black Matte Paint

Application Method:Spraying

Heat Resistance:Continuous resistance: 600–700℃; Peak direct flame: up to 800℃

Drying Method:Cure at 280°C for 15 minutes;, then cured by burner heat during use

Finish:Dark gray or matte black, stable color under high heat

Project Highlights

Resists direct flame without burning, charring, or chalking

Maintains adhesion under thermal expansion and contraction

Resistant to oxidation and grease, keeps clean in cooking areas

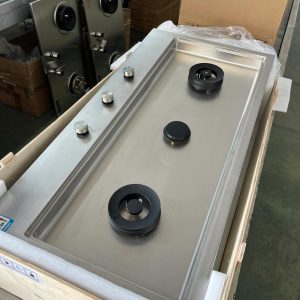

Before & After

Before: Burner head turned yellow, flaked, and showed rust after multiple uses

After: Coating remained intact with no discoloration or peeling, even after repeated flame exposure

Client Feedback

“This coating truly withstands heat. The burner heads no longer yellow or blacken after use. It gives a much more premium look, and our export clients are more satisfied with the detail quality.”