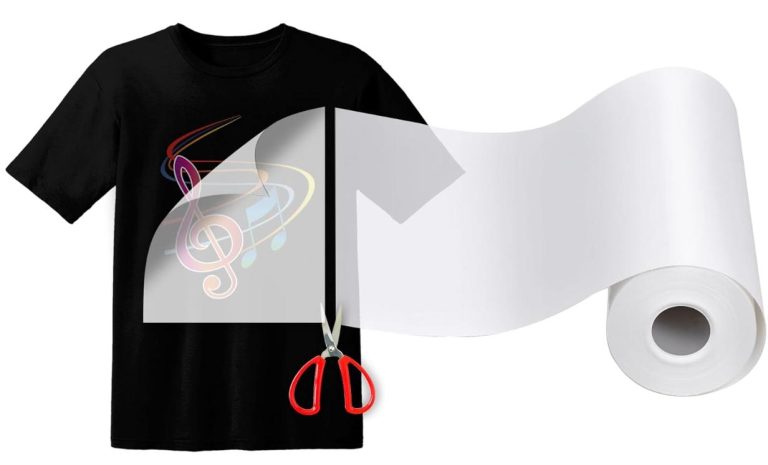

In digital printing, creating bright, high-quality images on dark or see-through materials like PET films, cotton, polyester, or mixed fabrics can be difficult. Standard coatings frequently face problems such as ink smearing, weak color intensity, or trouble moving patterns onto fabric. These issues often lead to poor results. White Ink Absorbent Coatings have become a game-changing answer, especially for Direct to Film (DTF) and heat transfer printing. These special coatings are made to boost ink intake, color richness, and transfer success. They are changing the printing field. This blog examines how White Ink Absorbent Coatings enhance print results on dark and clear materials. We focus on their important qualities: simple separation, strong color presence, static resistance, and outstanding ink soaking.

The Challenges of Printing on Dark and Transparent Materials

Dark and see-through materials, such as black cotton cloths or clear PET films, create special problems for digital printing:

Poor Ink Stickiness:

Dark surfaces often repel ink, causing weak or patchy images.

Weak Color Strength:

Getting bright colors on dark backgrounds needs a white ink base to improve coverage and shine. Ordinary coatings cannot provide enough support for this.

Ink Smearing:

Clear PET films may cause ink to spread or blur. This damages pattern sharpness.

Transfer Troubles:

Moving patterns from films to fabrics without leftover marks or warping is hard with normal coatings.

Static Electricity:

Electrical charge can disrupt ink application and transfer. This happens more in fast production settings.

White Ink Absorbent Coatings solve these problems. They use a special 3-in-1 formula that combines separation, ink-soaking, and sticky layers into one coating. This simplifies the printing steps and gives better results.

How White Ink Absorbent Coatings Improve Print Quality

White Ink Absorbent Coatings are designed to make printing on tricky materials work better. By putting many jobs into one coating, they guarantee high-quality prints with less production trouble. Below, we look at the key ways these coatings become essential.

Superior Ink Absorption for Crisp Patterns

The main job of White Ink Absorbent Coatings is to improve ink soaking. This makes sure white and colored inks stick well to the material. When put on PET films, these coatings form a non-shiny white surface that acts like a sponge. It firmly holds ink to create:

Sharp, Clear Patterns:

The coating stops ink spreading. This ensures exact, high-definition prints without smudges.

Rich Colors:

By giving a steady base for white ink, the coating improves the coverage and shine of later colored inks. This makes them stand out on dark fabrics or clear films.

Regular Outcomes:

The coating’s even ink soaking reduces unevenness, even on complex artwork.

For example, in DTF printing, White Ink Absorbent Coatings guarantee that detailed patterns printed on PET films stay sharp when moved to dark cotton or polyester clothes.

Easy Release for Seamless Pattern Transfer

One special quality of White Ink Absorbent Coatings is their separation ability. This lets patterns move smoothly from PET films to target materials like clothes or bags. It removes common problems such as:

Pattern Leftovers:

The coating ensures clean separation. This leaves no ink or marks on the PET film.

Undamaged Transfers:

The gentle separation prevents pulling or bending of the printed design during transfer.

Smooth Production:

Simple separation cuts the time and work needed for transfer. This speeds up output in busy printing places.

This quality is very valuable for digital printing companies making custom clothes. Perfect pattern transfer is critical for customer happiness there.

High Color Density for Vibrant Prints

White Ink Absorbent Coatings are made to maximize color richness. This ensures that prints on dark or clear materials are bold and eye-catching. Key gains include:

Better Coverage:

The white ink layer gives a solid base. This allows colors to stand out against dark backgrounds like black or navy fabrics.

Long-Lasting Brilliance:

The coating resists fading. It keeps color power even after many washes or sunlight contact.

Wide Material Use:

Whether used on cotton, polyester, nylon, or mixed fabrics, the coating gives steady, strong-color results.

This makes White Ink Absorbent Coatings perfect for uses like sportswear, fashion clothing, and promotional items. Bright visuals are vital in these areas.

Anti-Static Properties for Production Efficiency

Static electricity can upset digital printing by causing ink misplacement or stickiness troubles. White Ink Absorbent Coatings include static resistance to:

Stop Ink Rejection:

Static-free coatings ensure even ink application. This cuts flaws in fast printing.

Improve Handling:

Static resistance makes PET films easier to manage during printing and transfer. This lowers production delays.

Increase Toughness:

By reducing static-related damage, the coating extends the life of printed goods.

These qualities are key for makers wanting to keep speed and quality in large DTF printing work.

Applications of White Ink Absorbent Coatings

White Ink Absorbent Coatings are widely used in digital printing, especially for DTF and heat transfer uses. Key applications include:

| Application | Description |

| Custom Apparel | Used for printing bright designs on dark cotton, polyester, or mixed fabrics for T-shirts, hoods, and sport clothes. |

| Promotional Items | Applied to bags, hats, and other goods. Ensures high-quality, long-lasting prints on different materials. |

| Home Textiles | Allows printing on dark or clear fabrics for curtains, cushions, or furniture covers with sharp, lasting patterns. |

| Fashion Accessories | Supports high-definition prints on nylon or mixed fabric items like scarves or backpacks. |

These coatings are vital for digital printing material makers and OEM/ODM partners. They help deliver top-quality, personalized goods.

Why Choose White Ink Absorbent Coatings Over Traditional Coatings?

Ordinary coatings for PET films often need several layers (separation, ink-soaking, and sticky). This increases production difficulty and expenses. White Ink Absorbent Coatings provide a 3-in-1 answer that beats traditional options by:

Simplifying Steps:

One coating job replaces three separate applications. This cuts time and material costs.

Boosting Results:

Better ink soaking, strong color presence, and simple separation outperform multi-layer systems.

Supporting Green Goals:

The smoother process reduces waste. This matches environmental care aims.

Allowing Custom Mixes:

Formulas can be adjusted for special materials or production needs. This gives makers helpful flexibility.

For example, a traditional coating might require separate jobs for ink soaking and separation. This risks unevenness or irregular results. White Ink Absorbent Coatings instead give reliable, high-quality prints in one step.

About Foshan Konaz Technology Co., Ltd.

Foshan Konaz Technology Co., Ltd. is a top provider of White Ink Absorbent Coatings. They focus on advanced functional coating materials for digital printing and industrial uses. With over 15 years of knowledge, their 3,000-square-meter factory in Foshan, China has 30+ modern production units. They make 1,000 tons of coatings yearly. Their creative 3-in-1 White Ink Absorbent Coatings mix separation, ink-soaking, and sticky jobs into one coating. This gives simple separation, strong color presence, static resistance, and excellent ink soaking for DTF and heat transfer printing. Trusted worldwide, Konaz helps digital printing makers, OEM/ODM partners, and industrial suppliers. They drive speed and quality through modern answers.

Conclusion

White Ink Absorbent Coatings are changing digital printing. They solve the problems of printing on dark and clear materials. With their excellent ink soaking, simple separation, high color presence, and static resistance, these coatings deliver bright, tough, and exact prints for uses like custom clothes, promotional goods, and home textiles. By smoothing production with a 3-in-1 formula, they lower costs and boost speed. This makes them revolutionary for DTF and heat transfer printing. Working with trusted providers like Foshan Konaz Technology Co., Ltd., makers can use White Ink Absorbent Coatings to reach unmatched print quality and customer joy. Put money into these coatings to lift your printing jobs today.

FAQs About White Ink Absorbent Coatings

1. How do these coatings improve print quality on dark fabrics?

They create a non-shiny white base that ensures strong ink stickiness and high color richness. This stops smudging and lets bright colors stand out on dark materials like cotton or polyester. The result is sharp, long-lasting prints.

2. Can these coatings work on multiple materials?

Yes. They suit various materials including cotton, polyester, nylon, and mixed fabrics. Their flexible formula guarantees steady results across different surfaces. This makes them ideal for clothes and textile printing.

3. What makes these coatings simple to separate during transfer?

They contain a separation layer. This lets patterns move cleanly from PET films to target materials without marks or warping. This ensures smooth, high-quality transfers and better speed in DTF printing.

4. Do these coatings stop static troubles in printing?

Absolutely. They feature static resistance that lowers electrical charge during printing and handling. This guarantees even ink application and cuts production flaws, especially in fast settings.

5. How tough are prints made with these coatings?

Very tough. They resist fading, washing, and sunlight contact. The coating’s strong ink soaking and high color richness ensure long-lasting, bright patterns on dark or clear materials.